How shanghaimsd PETG Film Supports Efficient Thermoforming Results

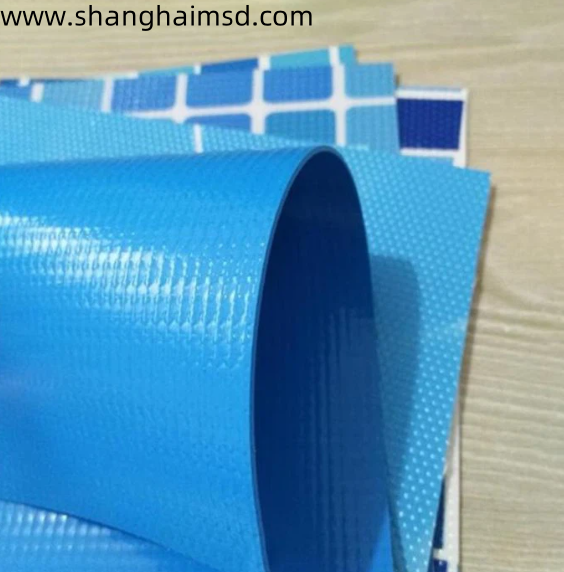

PETG Film is increasingly used in thermoforming applications for packaging, displays, and protective covers. Its chemical and physical characteristics make it adaptable to heat and pressure, allowing it to form detailed shapes without losing clarity or strength. This adaptability supports manufacturers in creating functional yet visually appealing products.

shanghaimsd provides PETG Film engineered to perform consistently under the controlled heating processes typical in thermoforming. The film softens uniformly, which allows it to be stretched or molded over molds with complex contours, producing smooth surfaces and stable forms. This makes it well-suited for packaging that requires transparency and durability.

One advantage of PETG Film in thermoforming is its balance between flexibility and rigidity. It can be formed into trays, clamshells, and other containers that protect contents while allowing clear visibility. Compared to some other plastics, it offers better impact resistance and less brittleness, which helps extend product usability.

Moreover, shanghaimsd’s PETG Film helps reduce material waste during production. Its stable thermal properties allow for precise temperature control, minimizing defects and the need for rework. This supports manufacturers in optimizing resources and maintaining consistent output quality.

For more information about thermoforming applications and PETG Film products, please visit: https://www.shanghaimsd.com/

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness